Alternative Systems

Convection Heating (with air);

Convectional heating systems work with the principle of passing the ambient air over a heat exchanger or generator by means of a fan and blowing it into the environment. The most commonly used convectional heating devices are unit heaters. Although the unit heaters have different models such as electric, natural gas, water coil, radial – axial fan, wall – ceiling type and so on, all of them work with the logic of moving the heat transferred to the air inside the device, to the desired area with the fan and therefore the air movement.

Since the density of hot air is less than cold air in places heated by blowing hot air, hot air rises and accumulates on the ceiling of the environment. In this case, as the ceiling height increases, it becomes more and more difficult to increase the air temperature at the floor.

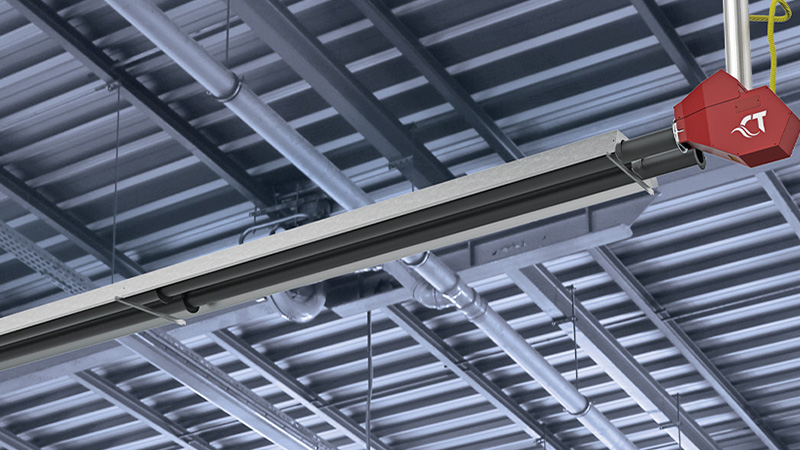

Tube Radiant Heating;

Although there are different models of tube radiant heaters such as single burner (straight type – u type) and multi burner (D-E-F-H type, etc.), their working principles are very similar. The burning gas in the combustion chamber moves forward in the specially coated tubes by transferring its heat to it with the help of fans and leaves the space through the chimney. The reflector over the tube performs the ambient heating by reflecting the heat emitted from the pipe towards the floor. In tube radiants, the temperatures on the pipe vary between 650 C (inlet) and 150 C (outlet).

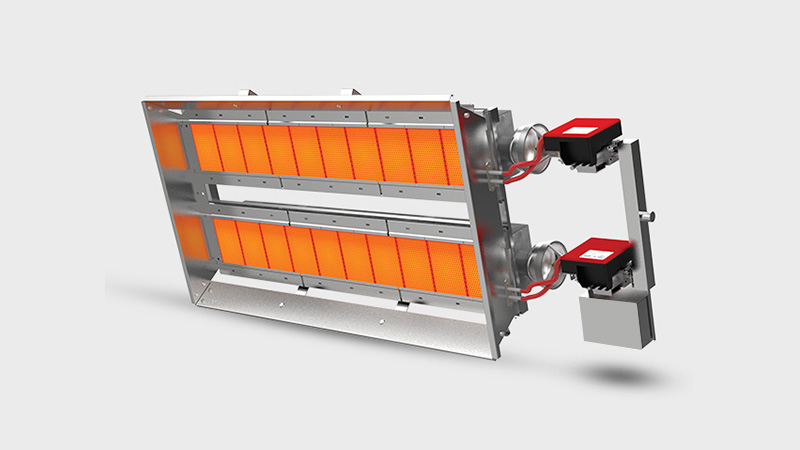

Ceramic Plate Radiant Heating;

Ceramic radiant heaters are also called open flame radiant heaters. The working principle of ceramic radiant heaters is based on the creation of an air-gas mixture by absorbing the appropriate amount of air from the environment with the venturi effect created when the gas enters the orifice. When the air-gas mixture reaches the ceramic plates, combustion takes place when it comes out from the holes on the plates and a short flame is formed on the plate surface.

The flame heats the ceramic plates and the radiation generated by the heated plates is directed to the desired area through the reflectors on the device. Surface temperatures of ceramic plate radiant heaters are around 900 C on average. In ceramic plate radiant heaters, combustion gases are thrown into the environment, no flue application is made.